Description

55 – 370kW Class

Discharge air volume 8.9 – 69.1 m3/min

Best-in-class performance with full-range line-up.

Energy Saving

Superior unit design for energy saving

New high-efficiency screw design enhances efficiency.

Completely resigned 2-stage compressor air end and reduced pressure loss within the package result in an 8% increase in efficiency. The water-cooled intercooler and aftercooler also feature the industry,s first plate-fin design, thus reducing air pressure loss to one-fifth.

Efficient energy saving with “Energy-Saving Logic” which minimize discharge pressure fluctuation

High performance screw unit

A completely new design of the two-stage compressor unit and a reduction in package internal pressure losses resulted in an energy saving by 8% over existing models. Furthermore, a plate-fin, the first in the industry, was incorporated for the water-cooled, inter cooler and after cooler, reducing the air pressure loss to 1/5.

Ultimate clean air

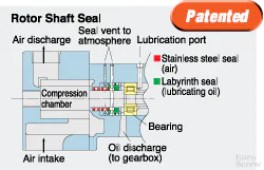

The oil-free design introduces absolutely no oil to the rotor chamber in the process. Stainless steel shaft-seal rings are used to prevent the generation of carbon dust, and Kobelco’s patented twin atmospheric shaft vents prevent lubricating oil from contaminating the compression chamber even during extended periods of unloaded operations.

Improved maintainability

Extended overhaul schedules

Recommended overhaul schedule for the 2nd stage was extended to every 6 years, whereas the 1st stage was extended to every 9 years (for an annual operation of 8,000 hours).

Annual maintenance involves changing the oil, oil filter element and exhaust cleaner only.

Frequency of capacity control operations

The life is extended to six times that of conventional models, with reliability and maintainability also improved.

Capability with 1.03 MPA specifications

All models are equipped with a compressor main unit that can operate with a pressure of up to 1.03 MPA.

Improvement on durability for ambient

Reviewing the total cooling system including design of coolers and cooling fan with safety margin, the compressor can operate even under ambient temperature of 45℃.

New type electronic monitor with liquid crystal display

Alternate operation function of two units-Graph display of operating history, weekly timer, daily report management, maintenance information, and operation status.

Safety & Peace of Mind

Totally enclosed fan-cooled motors are adopted to increase motor durability.

Totally enclosed fan-cooled (TEFC) motor with enough capacity is selected to reduce the motor coil temperature and motor bearing temperature, leading significant improvement of reliability. Motor coil thermal detector is equipped for safety aspect.

Protection features

Various improved protection for Electric parts.

Momentary interruption protection: Within 0.5 sec.

The compressor unit does not stop even when an momentary power failure (momentary power interruption, momentary power drop, temporary blackout) occurs, as long as the interruption time interval is less than the set value. The compressor unit is stopped when the power interruption duration exceeds the set value.

Built-in 12,000-V lightning surge killer and noise filter.

Automatic reset from power failure: 0.5 to 20 sec.

Example: Setting for recovery after power interruption: 5 sec.; power recovery standby time: 15 sec.

Environmental Considerations

Noise Reduction

Pulse noise is reduced by the perforated plate silencer, whereas the blade noise from the exhaust fan is reduced by optimum louver, thereby realizing top of its class low noise levels.

Exhaust cleaner that requires no oil mist breather piping

Conventional countermeasure for oil mist is discharging the oil mist outside of package by using oil mist breather piping, which may cause the environmental problem. To avoid pollution,it was necessary to install filter on the end of piping or corona separation-type mist collector. Newly developed Exhaust Cleaner utilizes super fine filter which can be installed inside the compressor package, and no more breather piping is required.

This Exhaust Cleaner has its self oil separation and recovery function. This can prevent differential pressure increase and can realize long term maintenance interval.